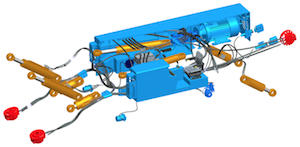

Digital hydraulic cantilever tunneling robot

Boom type roadheader is not only the main equipment in coal mine roadway construction, and after after technological transformation in the construction of railways, highways and other tunnel also has wide application prospect. However, boring machine work in the presence of many problems can not be avoided, such as operation labor intensity, poor working environment and working process of operation technology on large, roadheader robot is one of the ways to solve these problems, but also improve the tunneling machine operation ability, reduce production accidents and labor injury and one of the ways. Digital hydraulic technology can quickly realize the digital equipment, to lay the foundation for further information and intelligence. Digital hydraulic belongs to the incremental digital control of electro-hydraulic servo mechanism, can be in accordance with the requirements of the users, precise control of the velocity and displacement, work reliability is high, maintenance is also very simple, in the mines of roadheader can be applied.

The performance and characteristics of the digital hydraulic tunneling robot:

With remote control functions: the initial realization of remote control, the latter can realize half / full autonomous unmanned (intelligent) control;

With a teaching function: by hand operation slow manipulation a boring, boring machine can according to rock hardness automatic repetition of the whole process, so as to realize the automatic rapid excavation;

With active programming function: can also pre compiled a lot of driving procedures, the operator can only need to choose the program can realize the automatic tunneling;

Having the function of walking straight line or circular arc, the function of the arc can be set in advance;

According to the change of the driving force, the adaptive function of the driving speed is automatically changed to improve the driving efficiency;

Keep all hand exercises (instead of the original hydraulic pilot handle);

With a variety of fault prediction and alarm function, reduce the incidence of accidents;

Greatly reduce the production accident rate, reduce labor intensity and improve the working environment of workers;

Save energy consumption and improve work efficiency;

Simplify the hydraulic system and control components, reduce the failure point of the whole machine, saving part of the space, easy to repair and maintenance.

Visits: